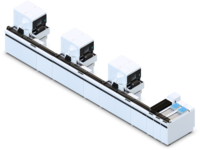

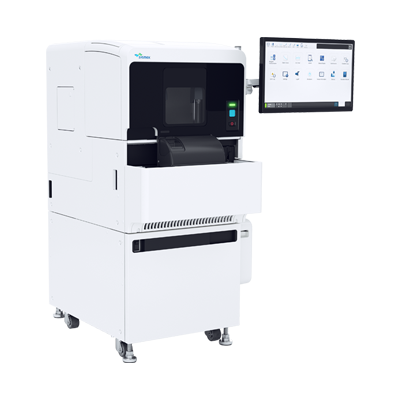

CN track

Coagulation transportation system

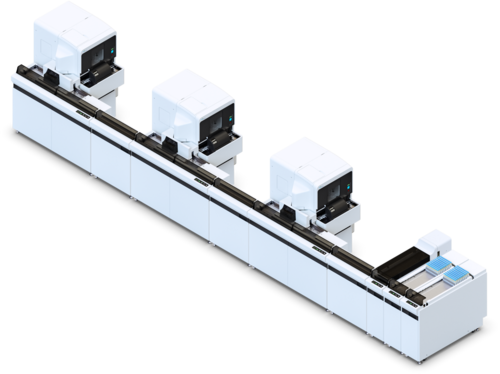

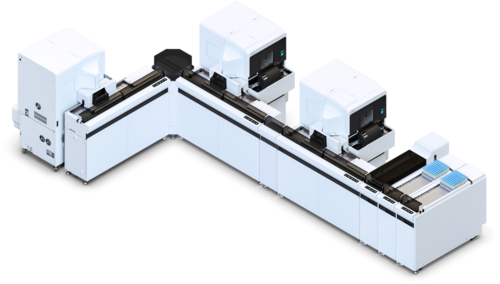

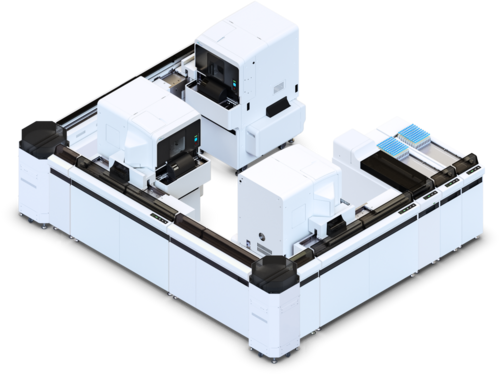

- Automate your haemostasis work area by connecting up to three CN-Series or CS-5100 analysers to a track system.

- Seamless workflow automation covering sample handling, measurement and rerun – with cap-piercing capability for extra safety. Open tubes can be processed, too.

- The modular and scalable configuration set-up allows adaptation to your workflow needs and is space-saving.

- Smart workflow support for full control through our software solutions Extended IPU and Caresphere™ *.

- Cost-effective island solution requiring only a moderate investment.

- CN track can be connected to third-party TLA systems**.

Wondering how to cope if test numbers keep rising?

The CN track is designed to handle high volumes of citrate samples by utilising intelligent technology to automate the haemostasis workflow in the laboratory. High productivity and flexibility help you optimise your haemostasis workflow – from sample registration until the results become available.

Sysmex’s modular haemostasis automation concept allows configuring the solution that fits best to your lab and adapts to your workflow needs. Being scalable, too, it will maintain its good fit and safeguard your investment.

Identical test panels can be set up on each of the connected analysers with an optimal sample distribution that ensures a smooth route from sample feeding to collection. Additionally, dedicated test panels can be configured on each of the connected analysers to ensure a smart sample distribution on the track, managed by the transportation controller software.

The cap-piercing functionality enables closed tube side aspiration from multiple tube types. With the optional rerun module, the same sample can be automatically redistributed to the same or different analyser for a rerun or reflex testing.

Our smart software solutions Extended IPU and Caresphere™* support the entire workflow in the best possible way, from order management to technical validation of the results – and beyond the analytical process towards lab management. This ensures full control of your haemostasis work area solution.

Your investment today holds the power to satisfy tomorrow’s needs.

*under development

**Contact your local Sysmex representative for details.

Productivity

- The high performance of the CN-Series and track components allow you to upscale sample throughput to deliver the turnaround time you need while increasing walk-away time even during peak hours.

- Cap-piercing system for capped sample tubes to reduce the biohazard risk and avoid sample decapping.

- Effective prevention of reading errors: sample tube rotation for sample barcode ID reading in the barcode terminal and the aspiration position.

- Flexibility in defining the sample feeding and collection points.

- Expand the initial configuration as required.

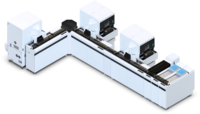

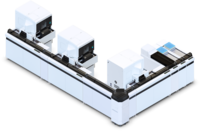

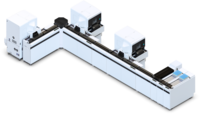

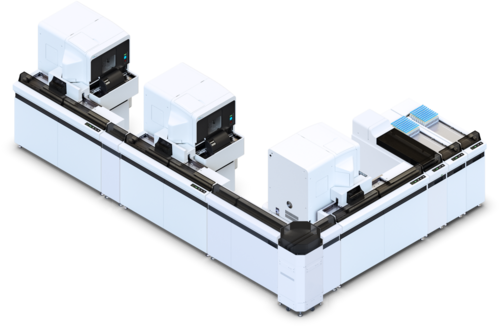

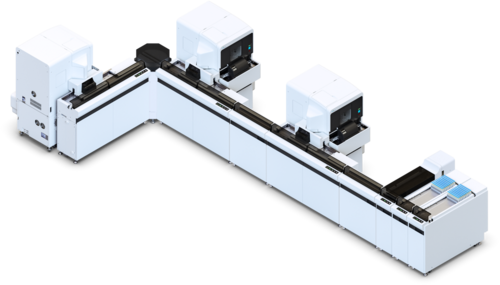

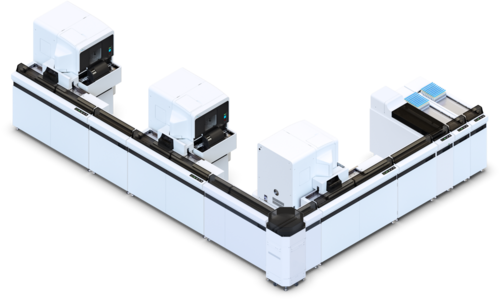

- If you do not have enough space for a linear set-up, alternative designs can be installed to suit your needs: inner L, outer L, inner U, outer U or Z shape.

- Optional rerun module to further increase workflow flexibility and walk-away time .

- Optional extensions of the sample feeding/collection areas to accommodate your peak hours’ high number of samples.

Intelligence

- All variations of the CN track containing CN-Series analysers include the Extended information-processing unit (Extended IPU) as standard. This intelligently routes and controls your sample, order and data workflow and provides full traceability for all citrate tubes with minimum cycle time.

- Intelligent sample distribution based on configurations of the analyser and transportation controller settings.

- You can integrate automatic rerun and reflex rules in the connected analysers (single aspiration) and/or through the Extended IPU solution (redistribution of the sample to the analyser for a second aspiration).

- Connected analysers can easily be switched to stand-alone mode without interfering with the track workflow.

- You can load samples to the track, the sampler of an individual analyser, and/or the STAT position – all of this is possible.

| Purpose | Workflow automation for an optimised processing of routine and speciality haemostasis testing |

| Number and model of connectable analysers | Maximum three analysers:

|

| Throughput | Up to 1,000 samples/h |

| Data storage | Sample results incl. graphics: 10,000 results/analyser Samples results incl. graphics with EIPU: up to 1,000,000 results |

| Control of sample and data flow | CN embedded software concept: information-processing unit (IPU), Extended IPU, transportation controller CT-90, Caresphere™* |

| Key automation components |

|

| TLA connectivity | Available. Contact your local Sysmex representative for details. |

*under development

Sysmex Europe SE

Bornbarch 1

22848 Norderstedt

Germany

+49 (40) 527 26 0

+49 (40) 527 26 100

Product documents

Regulatory documents

Regulatory documents, such as Instructions for Use, can be accessed with a valid My Sysmex login:

Go to My Sysmex